Case study

Steam elements made to measure

At a Dutch producer of instant coffee, a hot air flow of coffee grounds is used to dry the coffee grounds, the customer wanted a quick replacement of the existing steam-powered heat exchanger that was used in this process, and production had to stand still as little as possible.

Question

-

A Dutch producer of instant coffee uses a hot air stream to dry the coffee grounds.

-

A quick replacement of the existing steam-charged heating batteries is required.

-

Minimise production downtime

Solution

-

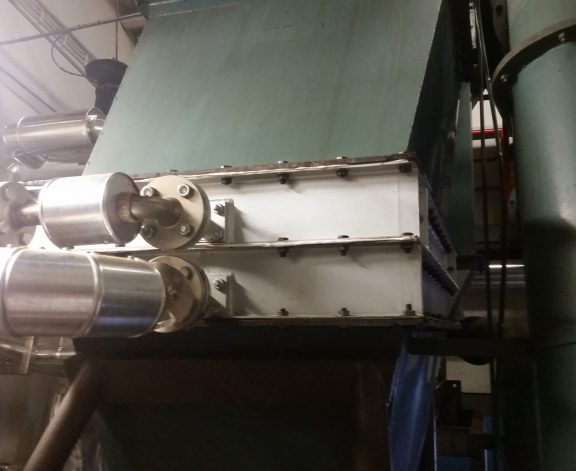

KiwiHesta started measuring on the spot and has within 3 weeks a number of custom made steam powered heating elements.

-

Including stainless steel frame

-

Also the bolt holes and connection pipes in exactly the right size so that they could be changed quickly.

-

Delivered: SRAS 660-2-1275 Stainless steel 316 steam powered elements with aluminium heavy duty vanes

-

Flanges and stainless steel 316 frame